Bad Actor

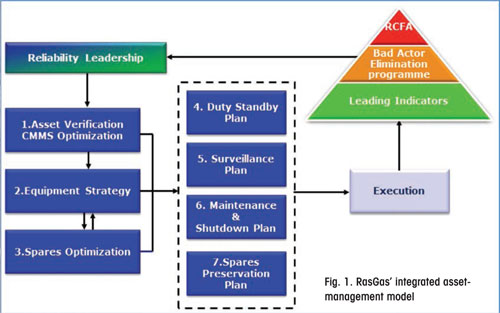

Bad Actor Management is a process by which harmful and unplanned failures are captured, prioritised and investigated to identify the root cause. Corrective actions are then developed and implemented to eliminate or mitigate a repeat failure.

By identifying and eliminating the repeat and/or significant failures reliability and productivity is increased and maintenance costs are reduced.

A bad actor program is designed to identify the gaps present in an organization’s current reliability strategies by analyzing unplanned failures based on the impact of each failure on maintenance cost and plant downtime. It is based on the famous Pareto principle, which states that 80 percent of the issues comes from 20 percent of the causes. By employing this principle, any organization can focus its attention on genuine and demanding issues related to plant maintenance and reliability, rather than overreacting on each failure.

The steps for a bad actor analysis are:

- STEP 1: Define the scope of the plant-level analysis, either to consider the whole plant at a time or designated process areas of the plant individually for a selected time period.

- STEP 2: Collect the work order history from the computerized maintenance management system (CMMS) for all assets.

STEP 3: Ensure the data in the work order consists of the equipment tag number, along with the order type, failure mode, cost of maintenance and associated downtime costs. - STEP 4: Use the collected data to prepare Pareto charts, so that equipment causing major failure costs ranks higher than others causing lower costs.

- STEP 5: Select for further review the bad actors, which per the Pareto analysis would be the top 20 percent of assets.

- STEP 6: Segregate the failure history of the selected assets for failure mode classification. Prepare the Pareto charts for failure modes existing in bad actors; the failure mode causing a frequent number of failures would rank higher than those causing fewer failures.

- STEP 7: Compare these failure modes against those present in the methodologies database. If the failure mode already exists, the recommendation should be reviewed and revalidated either to change the frequency or assign a new task. It is also necessary to revalidate or revise the maintenance procedure for each task reviewed.

- STEP 8: Review and revalidate the failure mode as per your root cause analysis (RCA) approach if the failure mode does not exist in the strategy database. Revalidating the new failure mode in RCA should result in determining a suitable task for that failure mode, such as a new preventive maintenance (PM) task or a redesign of the equipment part.

- STEP 9: Examine the outcome of the bad actor analysis, which should consist of PM amendments, additional PM tasks, redesign tasks, or others.

Please feel free to contact us today to find out more details about Bad Actor Management, how KTT management consultant will improve your plant’s productivity and performance availability, reliability and safety in various industries