RBI

In today’s highly competitive market, it has become a priority for continuous operations, particularly in the Oil & Gas sector, to avoid any unplanned shutdowns.

Additionally, worldwide regulatory incentives are also pushing for improved risk management aimed at protecting the environment and citizens from major industrial hazards. Companies must therefore ensure that their equipment is safe, reliable and does not create threats to the surrounding environment.

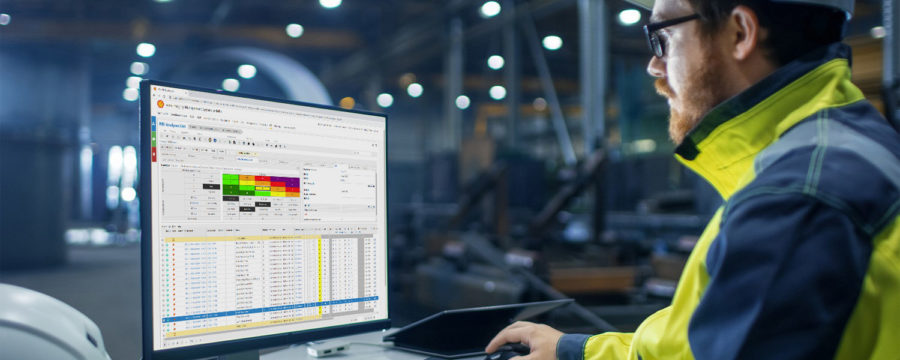

Risk-Based Inspection (RBI) is a process that identifies, assesses and maps industrial risks (due to corrosion and stress cracking), which can compromise equipment integrity in both pressurized equipment and structural elements.

RBI addresses risks that can be controlled through proper inspections and analysis. During the RBI process, engineers design inspection strategies (what, when, how to inspect) that most efficiently match forecasted or observed degradation mechanisms.

RBI addresses risks that can be controlled through proper inspections and analysis. During the RBI process, engineers design inspection strategies (what, when, how to inspect) that most efficiently match forecasted or observed degradation mechanisms.

KTT has developed an RBI approach following API 581, API 580 and EEMUA 159 (for tanks) principles. So enables KTT RBI service enables you to develop the best approach for your inspection activities using risk analysis and balance inspection costs and risk by using appropriate technology and software for inspection and maintenance planning. We can help you:

- Analyze the likelihood and consequences of failure

- Comply with all applicable governing regulations and guidelines

Develop a cost-effective inspection and maintenance program - Ensure mechanical integrity and reliability

- Prioritize and focus your inspection and maintenance resources on plant items and parts that pose the highest risks

Our risk based inspection services include:

- Assessment of process operations that will impact your production, operation, material integrity and degradation rates

- Development of a corrosion management plan

- Determination of the remaining lifetime of your assets

- Gap analysis

- Identification of operational risks, using recognized industry standards

- Identification of the appropriate inspection intervals

- Review of technical specifications and construction materials

- Specification of risk ranking level and determination of the respective risk acceptance level

- Specification of the necessary inspection and maintenance tasks

Contact us today to find out how our risk based inspection service can balance your inspection costs and risk by using appropriate technology for inspection and maintenance planning.